We Proudly Present Our Flagship Product CLC

At Nanolite, we're aim the construction industry with our innovation & sustainable building materials.

Superior Performance

Nanolite CLC blocks aren't just eco-friendly—they're also engineered for exceptional performance. With their lightweight composition, our blocks enable faster construction cycles, slashing labor costs and project timelines. Plus, their outstanding thermal and acoustic insulation properties ensure optimal comfort and energy efficiency in every structure.

Thermal Insulation

Nanolite's CLC blocks excel in thermal insulation with an impressive thermal conductivity rating of just 0.09 W/mK. This exceptional thermal insulation capability ensures that buildings constructed with Nanolite CLC blocks maintain comfortable indoor temperatures while significantly reducing heating and cooling costs.

Lightweight Blocks

The reduced dead load of Nanolite CLC blocks translates to lower requirements for reinforcement bars (rebars), further minimizing construction expenses. Builders can optimize the design and layout of reinforcement, saving both time and resources without compromising structural integrity. Additionally, the lightweight nature of CLC blocks simplifies handling and installation, streamlining the construction process and reducing labor costs.

Why Nanolite Light Weight Concrete ?

Dead Load Reduction

- Reduced Structural Costs: CLC blocks are lighter than traditional concrete blocks, resulting in decreased structural requirements for foundations, beams, and columns. Builders can use smaller, lighter support elements, leading to savings in materials and labor costs during construction.

- Lower Foundation Costs: The lighter weight of CLC blocks reduces the load exerted on the foundation, allowing for simpler and more economical foundation designs. This can result in cost savings on excavation, concrete, and other foundation materials.

- Transportation and Handling Savings: CLC blocks are easier to transport and handle due to their reduced weight. This can lead to lower transportation costs and reduced manpower requirements for handling during construction, contributing to overall project savings.

- Energy Efficiency: The excellent thermal insulation properties of CLC blocks contribute to energy savings throughout the life of the building. Reduced heating and cooling requirements result in lower energy bills for occupants, enhancing the building's long-term cost-effectiveness.

- Reduced Maintenance Costs: CLC blocks are durable and resistant to weathering, reducing the need for frequent maintenance and repairs. This translates to long-term cost savings for building owners over the lifespan of the structure.

- Faster Construction: Lighter weight CLC blocks can be installed more quickly than traditional concrete blocks, leading to shorter construction timelines and reduced labor costs. Projects are completed faster, allowing for earlier occupancy and potential cost savings on financing and overhead.

Thermal Insulation

- Energy Efficiency: CLC blocks have excellent thermal insulation properties, which means they can help maintain stable indoor temperatures throughout the year. In colder climates, CLC blocks trap heat indoors, reducing the need for extensive heating. Similarly, in warmer climates, they prevent heat from penetrating the building, thus reducing the reliance on air conditioning. By reducing the need for heating and cooling, CLC blocks significantly lower energy bills, leading to substantial cost savings over time.

- Reduced HVAC System Size: The superior thermal insulation provided by CLC blocks allows for the downsizing of heating, ventilation, and air conditioning (HVAC) systems. Because CLC blocks help maintain indoor temperatures more efficiently, HVAC systems can be designed with lower capacity requirements. This results in cost savings during the initial installation of HVAC systems and reduces ongoing operational costs due to lower energy consumption.

- Long-Term Savings: Investing in CLC blocks for their thermal insulation properties offers long-term financial benefits. While the upfront cost of CLC blocks may be slightly higher than traditional concrete blocks, the energy savings achieved over the lifespan of the building far outweigh the initial investment. Additionally, CLC blocks require minimal maintenance and have a long service life, further contributing to cost savings over time.

- Compliance with Energy Efficiency Standards: Many regions have stringent energy efficiency regulations for buildings. By using CLC blocks with superior thermal insulation properties, builders can easily meet or exceed these standards without the need for additional insulation materials or costly modifications. This ensures compliance with regulations while minimizing expenses associated with energy audits or retrofitting.

- Improved Comfort and Productivity: Beyond cost savings, the thermal insulation provided by CLC blocks enhances occupant comfort and productivity. Stable indoor temperatures create a more comfortable living or working environment, leading to increased satisfaction among occupants and potentially higher productivity levels in commercial settings.

High Strength

- Unmatched Strength: Nanolite's CLC blocks are engineered to deliver unparalleled strength, surpassing industry standards and setting new benchmarks. With a compressive strength of up to 2300 psi (pounds per square inch), Nanolite CLC blocks stand as the epitome of structural integrity and reliability. This remarkable strength ensures that buildings constructed with Nanolite CLC blocks withstand the test of time, providing long-lasting performance and peace of mind to builders and developers.

- Proven Durability: Nanolite CLC blocks are renowned for their exceptional durability, capable of withstanding harsh environmental conditions and heavy loads without compromising structural integrity. Proven through rigorous testing and real-world applications, Nanolite CLC blocks have earned the trust and endorsement of prestigious organizations worldwide. From Dubai Municipality to Pakistan FWO Army and projects in China, Nanolite's durability has been demonstrated across diverse environments and demanding conditions, reaffirming its status as the go-to choice for resilient construction materials.

- Certified Excellence: Nanolite's commitment to quality and excellence is reflected in its certifications and endorsements from leading authorities in the construction industry. With certifications from renowned institutions and approvals from regulatory bodies, Nanolite CLC blocks meet and exceed the highest standards of quality, safety, and performance. Builders and developers can trust Nanolite's proven track record of excellence, backed by certifications that attest to its superiority in the global market.

- Innovative Engineering: Nanolite continually pushes the boundaries of innovation, investing in research and development to enhance the performance and versatility of its CLC blocks. Through cutting-edge engineering and advanced manufacturing processes, Nanolite achieves optimal strength-to-weight ratios, resulting in lightweight yet incredibly robust CLC blocks that defy conventional limitations. This commitment to innovation ensures that Nanolite remains at the forefront of technological advancements in the construction industry, providing builders with solutions that inspire confidence and deliver exceptional results.

No Plaster

- Customization: Nanolite understands that every construction project is unique, with specific requirements and challenges. That's why we offer customizable CLC block solutions that are tailored to the client's precise specifications. Whether it's adjusting block dimensions, altering compressive strength, or incorporating specific additives, Nanolite works closely with clients to develop CLC blocks that perfectly align with their project needs, eliminating the need for unnecessary planster and optimizing material usage.

- Efficient Production Processes: Nanolite leverages advanced manufacturing processes and state-of-the-art technology to ensure efficient production of CLC blocks. By optimizing production workflows, minimizing material wastage, and maximizing output, Nanolite streamlines the manufacturing process to reduce costs while maintaining exceptional quality and consistency. This efficiency translates into cost savings for clients without compromising on product performance or durability.

- Sustainable Solutions: Nanolite is committed to sustainability in all aspects of its operations, including CLC block production. By utilizing eco-friendly materials, reducing energy consumption, and minimizing environmental impact throughout the production process, Nanolite delivers sustainable solutions that not only reduce costs but also contribute to a greener future. With Nanolite CLC blocks, clients can achieve their construction goals while minimizing their carbon footprint and promoting environmental stewardship.

- Continuous Improvement: Nanolite is dedicated to continuous improvement and innovation, constantly seeking ways to enhance the efficiency and cost-effectiveness of its CLC block solutions. Through ongoing research and development, process optimization, and feedback from clients and industry experts, Nanolite remains at the forefront of technological advancements in CLC block production. This commitment to excellence ensures that clients always receive the most efficient and cost-effective solutions tailored to their needs.

Low Water Absorption

- Enhanced Durability: Low water absorption in CLC blocks means they are less susceptible to damage caused by moisture, such as cracking, spalling, and degradation of structural integrity. This enhances the durability and longevity of buildings constructed with CLC blocks, ensuring they maintain their strength and aesthetic appeal over time, even in humid or wet environments.

- Reduced Maintenance Costs: Because CLC blocks have low water absorption, they require minimal maintenance to prevent moisture-related issues. This translates to cost savings for building owners over the lifespan of the structure, as there is less need for repairs, sealing, or waterproofing treatments to mitigate water damage.

- Improved Thermal Performance: Water absorption can negatively impact the thermal insulation properties of building materials. By minimizing water absorption, CLC blocks maintain their thermal efficiency, helping to regulate indoor temperatures and reduce heating and cooling costs for building occupants.

- Resistance to Mold and Mildew: High moisture levels can create conditions conducive to mold and mildew growth, leading to health hazards and aesthetic concerns. CLC blocks with low water absorption are less prone to mold and mildew, providing a healthier indoor environment and preserving the cleanliness and appearance of the building interior.

- Suitability for Exterior Applications: CLC blocks with low water absorption are well-suited for exterior applications, such as facades, boundary walls, and landscaping features. Their resistance to moisture ingress helps to protect the structural integrity and appearance of the building envelope, ensuring long-term performance and curb appeal.

Earthquake Resistance

- Lightweight Nature: CLC blocks are significantly lighter than traditional concrete blocks, reducing the overall weight of the structure. This lightweight characteristic minimizes the inertia force exerted during an earthquake, thereby decreasing the structural stress and potential damage to the building.

- High Strength-to-Weight Ratio: Despite their lightweight composition, CLC blocks exhibit impressive strength, providing structural stability and resistance to seismic forces. Nanolite's CLC blocks are engineered to achieve high compressive strengths, ensuring structural integrity and durability even under dynamic loading conditions during an earthquake.

- Damping Properties: The cellular structure of CLC blocks allows them to absorb and dissipate energy during seismic events, providing effective damping and reducing the amplitude of vibrations transmitted through the structure. This damping effect helps to minimize structural deformation and prevents excessive movement, enhancing the building's overall seismic performance.

- Flexibility and Ductility: CLC blocks offer inherent flexibility and ductility, allowing them to deform and absorb seismic energy without catastrophic failure. This flexibility helps to redistribute seismic forces throughout the structure, reducing localized stress concentrations and preventing collapse or significant damage.

- Code Compliance: Nanolite's CLC blocks are manufactured in accordance with industry standards and building codes, ensuring compliance with seismic design requirements and specifications. By using CLC blocks that meet regulatory standards, builders can achieve structures that are inherently earthquake-resistant and provide greater safety for occupants.

- Testing and Certification: Nanolite conducts rigorous testing and quality control measures to verify the earthquake resistance of its CLC blocks. Through laboratory testing and real-world applications, Nanolite ensures that its CLC blocks meet or exceed the seismic performance criteria established by relevant authorities and engineering standards.

Low Cost

- Lower Material Costs: CLC blocks typically use less cement compared to traditional concrete blocks, as they incorporate lightweight aggregates and foam to achieve their desired properties. This reduction in cement content translates to lower material costs per block, contributing to overall project savings.

- Reduced Structural Costs: CLC blocks are lighter in weight than traditional concrete blocks, resulting in reduced structural requirements for foundations, beams, and columns. Builders can use smaller, lighter support elements, leading to savings in materials and labor costs during construction.

- Energy Efficiency: The thermal insulation properties of CLC blocks help to regulate indoor temperatures, reducing the need for heating and cooling. By minimizing energy consumption for climate control, CLC blocks contribute to lower utility bills over the lifespan of the building, resulting in significant cost savings for building owners and occupants.

- Faster Construction: CLC blocks are easier to handle and install compared to traditional concrete blocks due to their lightweight nature. This results in shorter construction timelines, reduced labor costs, and faster project completion, allowing builders to save money on overhead expenses and potentially earn earlier returns on investment.

- Long-Term Savings: Beyond initial construction costs, CLC blocks offer long-term savings through reduced maintenance and repair expenses. Their durability, resistance to weathering, and low water absorption properties help to minimize the need for costly repairs or replacements over time, resulting in lower life-cycle costs for building owners.

- Customization for Efficiency: Nanolite offers customization options for CLC blocks, allowing builders to tailor the blocks' dimensions, thermal properties, and density to optimize efficiency and cost-effectiveness for specific project requirements. This flexibility enables builders to achieve the desired balance between performance, cost, and sustainability.

Sustainable Life

- Recycled Materials: CLC blocks often incorporate industrial by-products such as fly ash, a waste material generated from coal combustion. By utilizing these recycled materials as aggregates in CLC production, the environmental impact associated with waste disposal is minimized, contributing to sustainable resource management and reducing the demand for virgin materials.

- Energy Efficiency: The lightweight nature of CLC blocks reduces energy consumption during transportation and handling, leading to lower carbon emissions and energy usage compared to traditional concrete blocks. Additionally, the thermal insulation properties of CLC blocks help to regulate indoor temperatures, reducing the need for artificial heating and cooling and further enhancing energy efficiency over the lifespan of the building.

- Durability and Longevity: CLC blocks exhibit excellent durability and resistance to weathering, ensuring a long service life for structures built with CLC. Unlike traditional concrete, which may be prone to cracking and degradation over time, CLC maintains its structural integrity and aesthetic appeal for decades, reducing the need for frequent maintenance and repairs and extending the lifespan of the building.

- Low Environmental Impact: The production process of CLC blocks typically involves lower carbon emissions and environmental impact compared to traditional concrete manufacturing. With reduced cement content and energy consumption, CLC production results in fewer greenhouse gas emissions and less environmental pollution, making it a more sustainable choice for construction projects.

- Versatility and Adaptability: CLC blocks offer versatility in design and construction, allowing for innovative and resource-efficient building solutions. Their lightweight nature and customizable properties enable architects and builders to optimize material usage, minimize waste, and achieve sustainable design objectives while meeting performance and aesthetic requirements.

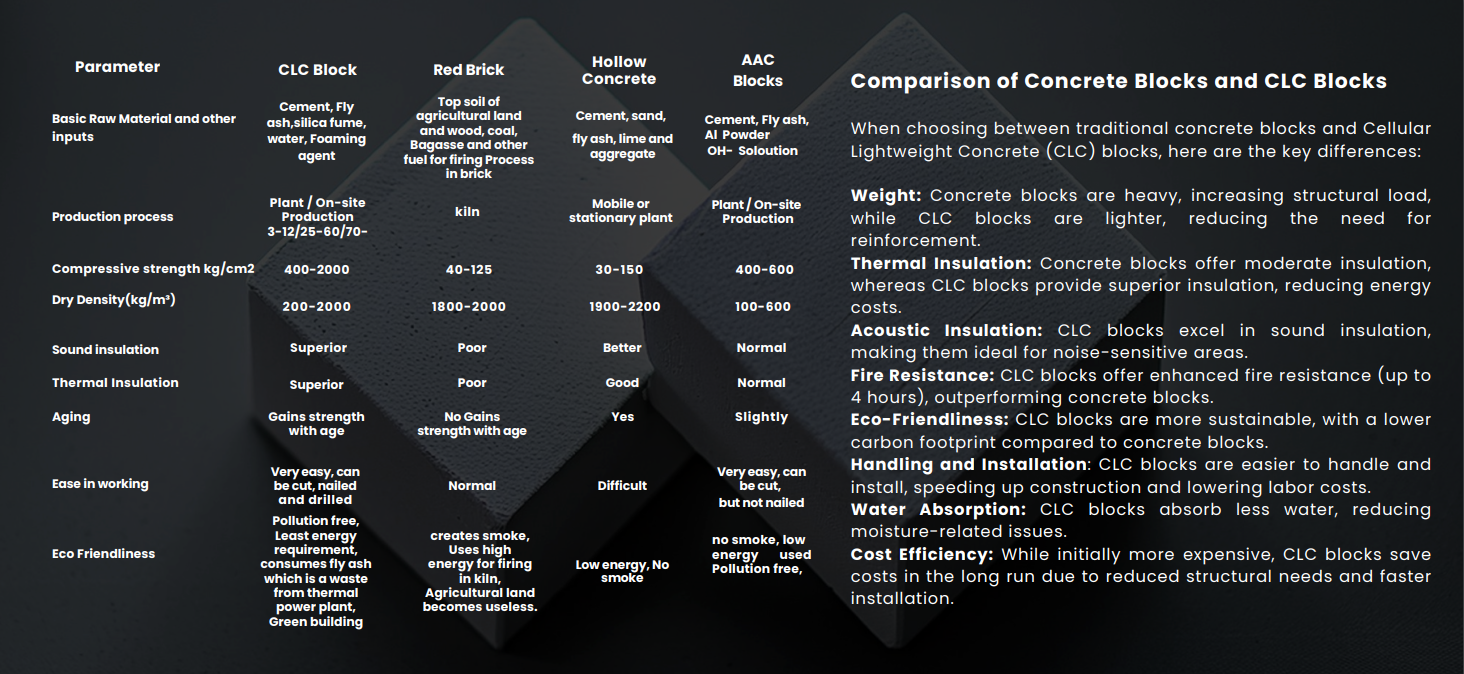

Comparison Sheet (SC)

At Nanolite, we offer our clients a wide range of options to customize their CLC (Cellular Lightweight Concrete) blocks according to their specific project requirements.